Small changes can lead to a huge experience upgrade-this is particularly evident in the design of masks. In particular, the introduction of the built-in nose bar not only solves the problem that the traditional plane mask cannot fully fit the face, but also provides the wearer with better comfort and safety.

With the support of scientific technology, today's nose bridge is no longer limited to a single material, but combines the advantages of flexibility and strength. They are made of polymer composite materials, which can ensure flexibility and at the same time have enough hardness to support the entire mask shape. Such innovations have greatly enhanced user satisfaction.

Different life scenarios correspond to different functional requirements. For example, during the daily commute, people tend to be light and easy to carry type; and in some special professional environment such as construction site or laboratory, it is more suitable for rugged and has good filtration performance of the product version. Therefore, it is particularly important to choose the right embedded metal strip.

At the same time, the existence of the nose bridge is not only for aesthetic considerations. In fact, it plays a vital role in maintaining the good sealing state of the mask. The correct installation position allows the air circulation path to be controlled, reduces the chance of fogging of the glasses, and helps to keep the mouth area dry and fresh.

It is worth mentioning that modern consumers are paying more and more attention to the possibility of personalized options. Many brands now allow customers to adjust parameters such as tightness and even bending angle according to their personal preferences. This not only meets the specific requirements of specific groups of people (such as children or the elderly), but also allows each user to obtain a unique and best-fit solution.

Looking at this from a professional perspective, we find that health care systems and industrial enterprises of all types rely heavily on the reliable support service provided by this seemingly simple component. Especially in the face of public health emergencies, the efficient operation of professional-grade protective equipment is inseparable from the precise calibration of each fine structural details of the arrangement is directly related to the overall level of effectiveness.

When we stand in front of a purchase decision, please keep in mind a few key factors that can help us make a wise choice:

- -Whether the material is safe, non-toxic, skin-friendly, compatible, good contact reaction, less allergy risk,

- -exquisite and meticulous production workmanship without rough edges to avoid scratching the skin and causing discomfort or even serious damage;

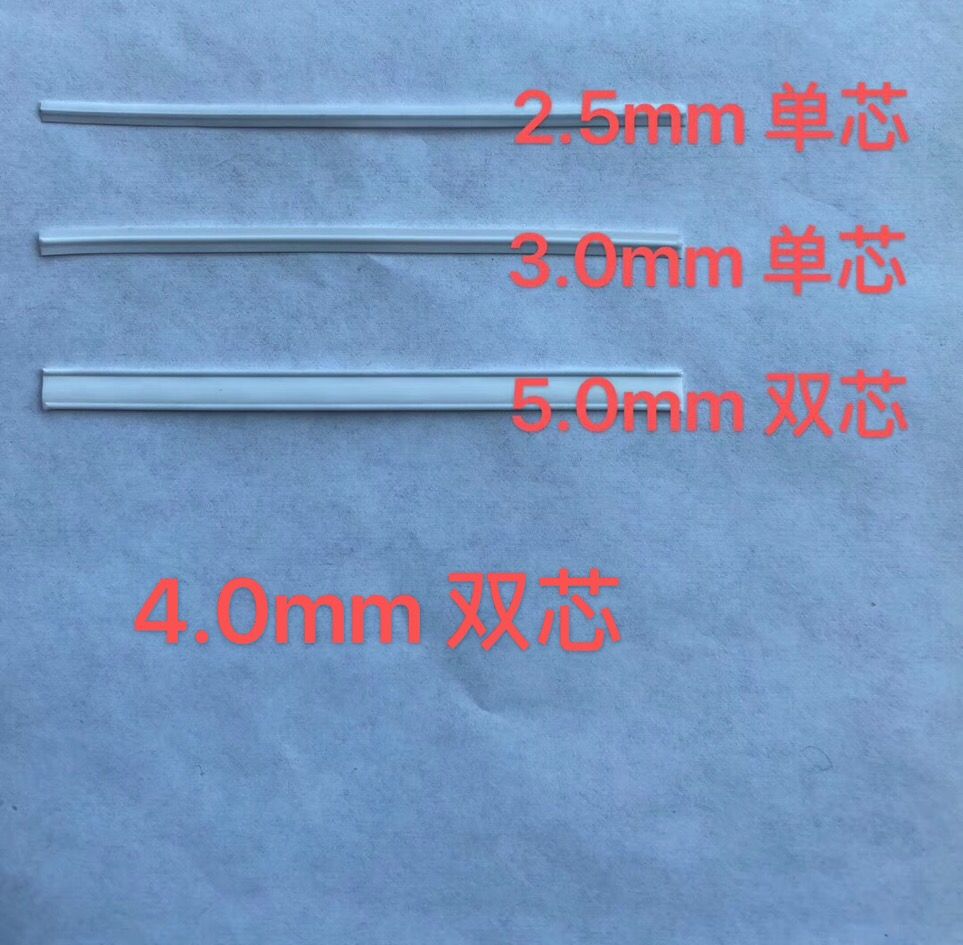

- -complete dimensions and specifications, wide adaptation range, mainstream models covering mainstream markets, and large selection space for reference and comparison.

Looking ahead, as the pace of technological progress accelerates, we can foresee that intelligent design concepts will further promote the innovation and development process in the field of protective equipment. Imagine how exciting a new generation of high-tech products that automatically sense temperature and humidity changes and immediately adjust their morphology to current conditions will be?